The Double Haven: a 1993 Feadship of remarkable technical sophistication

In 1993, Akerboom delivered the yacht equipment on a Feadship of remarkable technical sophistication— “Double Haven”, Building Number 647, designed to explore the coastlines of Australia and the Indonesian Archipelago. Acting as a mother ship, its purpose was to enable coastal exploration, with an 8-meter-long catamaran tender, aptly named "Double Happiness," facilitating beachside activities such as barbecues and camping.

This project posed unique challenges for Akerboom Yacht Equipment, particularly regarding the engineering solutions required for the overhead sliding cranes and the expansive swim platform. The overhead cranes were tasked with an extraordinary reach, allowing the catamaran tender to be launched over an open hatch. This setup demanded precise engineering, as the long sliding beams extended into the yacht’s salon, where space was already at a premium due to the climate control systems and interior fittings. The complexity of integrating these systems without compromising the yacht’s functionality underscored the depth of Akerboom’s expertise.

The challenge did not stop at the technical requirements; the cranes also needed to meet stringent class approval standards, all while maintaining a seamless integration with the vessel’s design. Material selection was critical, with special attention to preventing corrosion in the harsh maritime environment. At a time when electric propulsion was still uncommon, Akerboom’s decision to implement an electric drive for the cranes demonstrated foresight and technical innovation.

The design of the yacht’s boarding ladder also marked a first for Akerboom. Capable of swivelling 90 degrees, it featured self-levelling steps, a technical advancement that ensured safe boarding from the shore. Extending the ladder beyond the ship’s rub rail presented further engineering challenges, as space for the ladder’s mechanism was constrained, yet maintaining a comfortable and practical width was essential.

Equally notable was the design of the swim platform, almost double the width of conventional platforms. This required the addition of a centre bearing to manage the load. Here, too, space limitations near the hatch meant that installing the necessary drive and locking mechanisms involved careful problem-solving. Even after the yacht’s construction, when the owner requested a railing be added to the platform, Akerboom adjusted the hinge system to accommodate the late-stage change, reaffirming their commitment to precision.

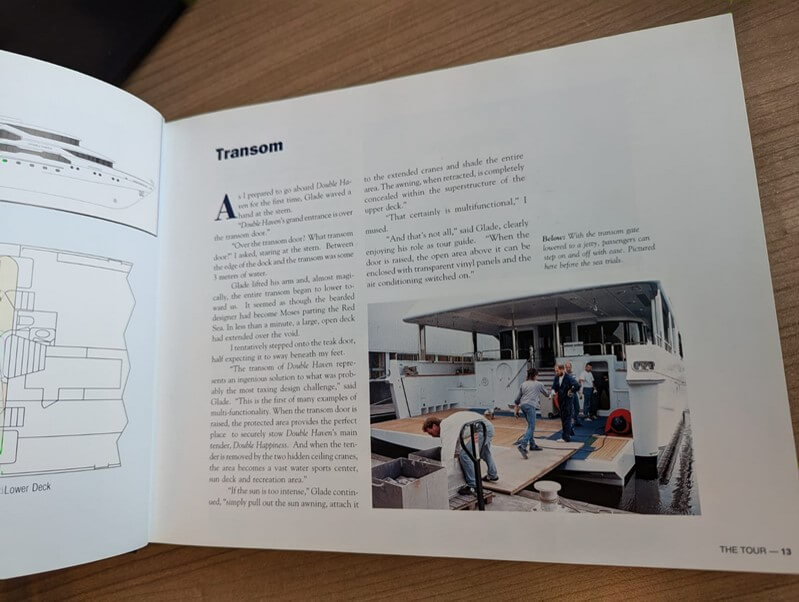

Perhaps the most striking feature of the yacht is its transom door. The owner vividly recalls his first experience stepping aboard, describing the moment as “magical.” As he stood at the stern, the entire transom lowered, extending a large teak platform over the sea. He likened the transformation to “Moses parting the Red Sea,” a testament to the ingenuity behind the design. This platform served multiple purposes: stowing the tender, providing space for water sports, and transforming into a sun deck, complete with a retractable awning cleverly concealed within the superstructure. When required, the area could be enclosed, with air conditioning providing comfort—an example of the multi-functionality that defined this project.

Three decades later, Akerboom remains connected to this yacht. In 2024, the service team returned to perform routine maintenance on the original systems they installed. The fact that the cranes, boarding ladder, and swim platform remain fully operational speaks to the lasting quality and foresight of Akerboom’s engineering solutions. Despite the challenges faced during construction, the equipment continues to perform as intended, underscoring Akerboom’s enduring commitment to craftsmanship and technical excellence.

As this yacht embarks on new journeys, Akerboom wishes its crew and guests safe and memorable voyages, confident that the solutions crafted decades ago will continue to support their adventures for years to come.